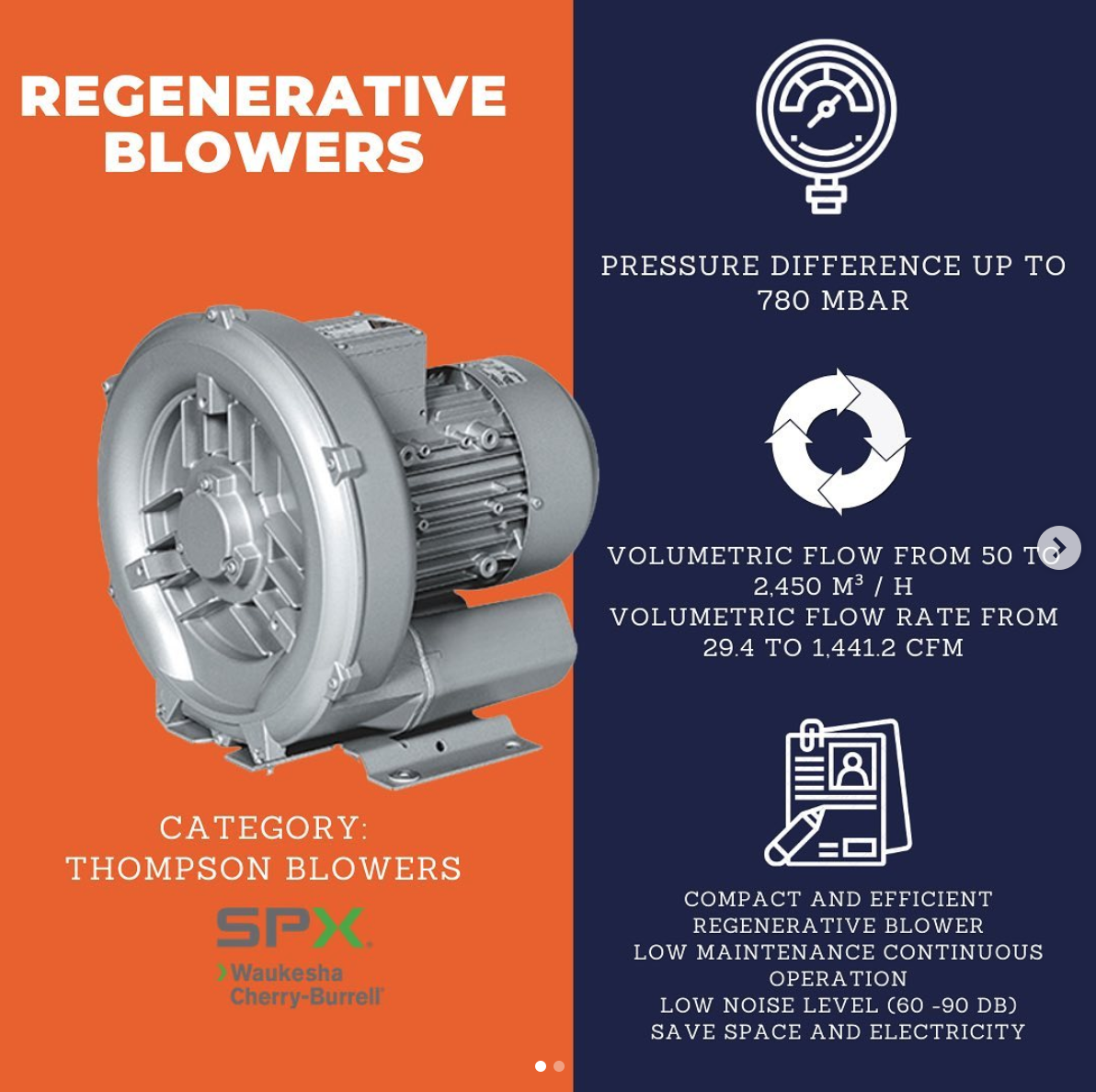

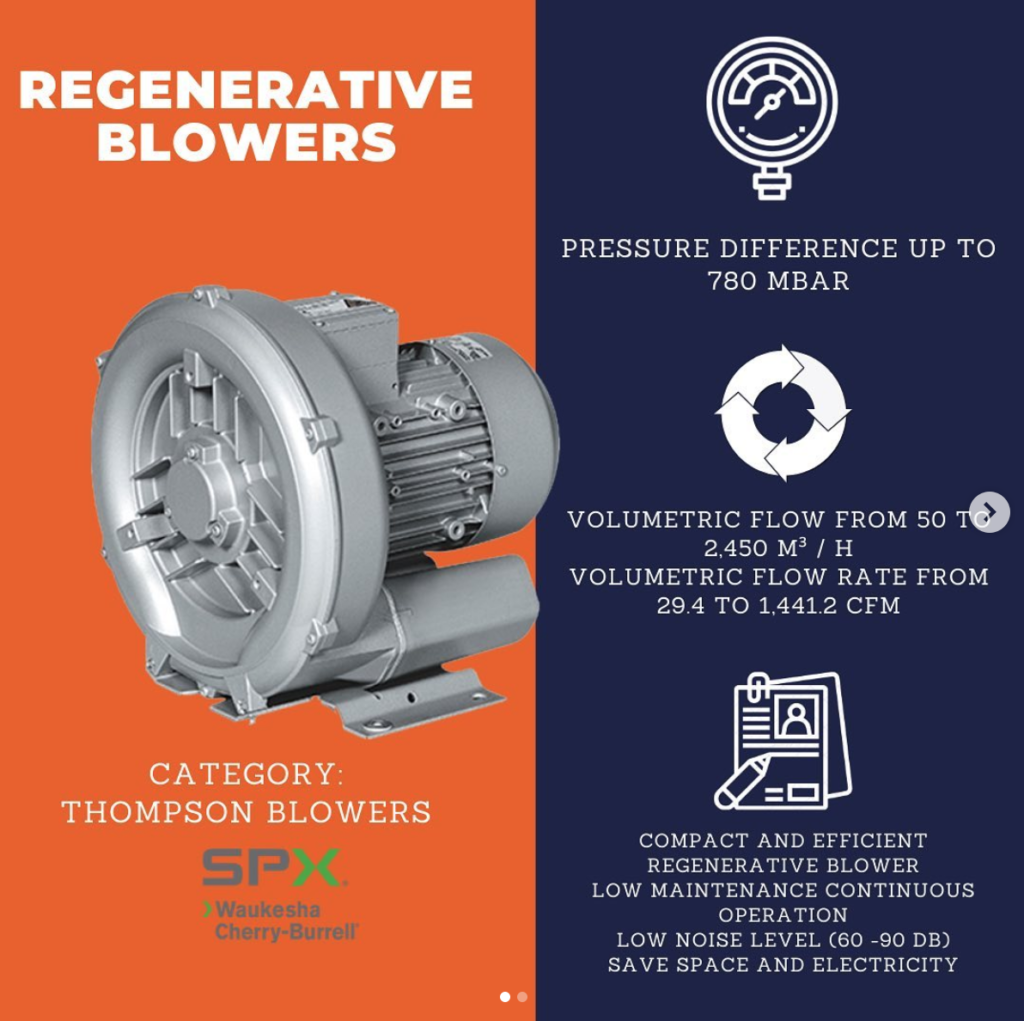

The regenerative blower is also known as a side-channel blower. It is so named because compared to axial and radial machines, it generates a substantial pressure ratio. Its characteristics make it applicable in a wide range of operating conditions with reasonable efficiency.

Below we will tell you the advantages of using the regenerative blower to generate the processed air required in a plant.

Advantage

In operation, they are normally quieter than other types of blowers.

The increase in production capacity, because regenerative blowers were designed to generate the necessary balance between volume and pressure to obtain an optimal flow of the product.

If you want to read more about regenerative blowers click here.

It consumes much less power at a comparable operating point. Their installation costs are low and in many cases zero. This is due to the possibility of placing the equipment in a strategic location within the plant, thus ensuring that all electrical and pneumatic connections are preloaded and wired within the factory.

The reduction in weight, size, and better integration, conservation of resources and has a positive effect on the energy efficiency of the regenerative blower.

Optimizing the individual components of a regenerative blower achieves major improvements, even for devices that have been around for some time.