Today we want to talk to you about the submersible water pump, and industrial equipment that has been created for different uses and that has several characteristics that you may want to know about.

Water pumps, there is a great variety on the market.

As we have said, there are different types of water pumps, including the submersible water pump, they are designed for different uses depending on the needs.

- Water pumps for industrial use.

- Water pumps for domestic use.

- Water pumps with different fuels, diesel, gasoline, or electricity.

- Clean or residual water pumps.

- Submersible or outdoor pumps.

Common uses of water pumps:

For construction: For water supply, including pneumatic systems.

To increase supply: To increase the pressure in any supply system.

For drinking water: Used in domestic water supply systems.

For fire protection systems: Which provide continuous pressure and comply with current regulations.

For hot water circulation: They recirculate the water in a closed system.

For the extraction of water in wells, reservoirs, fountains, or cisterns that are at a certain depth.

For the evacuation of water due to flooding.

What are the characteristics of the submersible water pump?

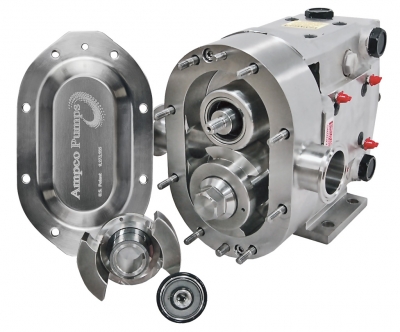

To complete this information, we are going to talk about a type of water pump that is widely used and that can offer good advantages. A submersible water pump has an impeller sealed to the casing, and it is immersed in the liquid to be pumped. The advantage of this type of pump is that it can offer significant lifting force, as it does not depend on external air pressure to make the liquid rise.

The submersible water pump is electric and is mainly used to extract water from wells, reservoirs, fountains, or cisterns at different depths, for their conservation, they are designed with a special casing that protects them from oxidation and corrosion.

How does a submersible water pump work?

The system includes several rotating impellers that are installed in series to increase pressure. The energy used to turn the pump is obtained from a low voltage electrical network that drives a motor specially designed to work at temperatures of up to 150ºC.

In most applications, asynchronous AC motors are used to drive a radial centrifugal pump, which can be multi-stage connected in series. Submersible pumps can also work with a suction pipe, placing the pump above the level of the tank. However, to work they have to be primed with water so that the water column communicates the pump with the tank. The suction pipe must not be excessively high so that the pressure in the pump does not drop excessively and prevent its cavitation.

The pumped liquid, as it circulates the engine, is also responsible for cooling it. Also, if the pump is located outside the tank, there is a possibility that gasoline will leak and could cause a fire. Some types of pumps are not suitable for certain applications, such as pumping hot water or flammable liquids.

If you are interested in receiving a quote or consulting with our representatives, click HERE.