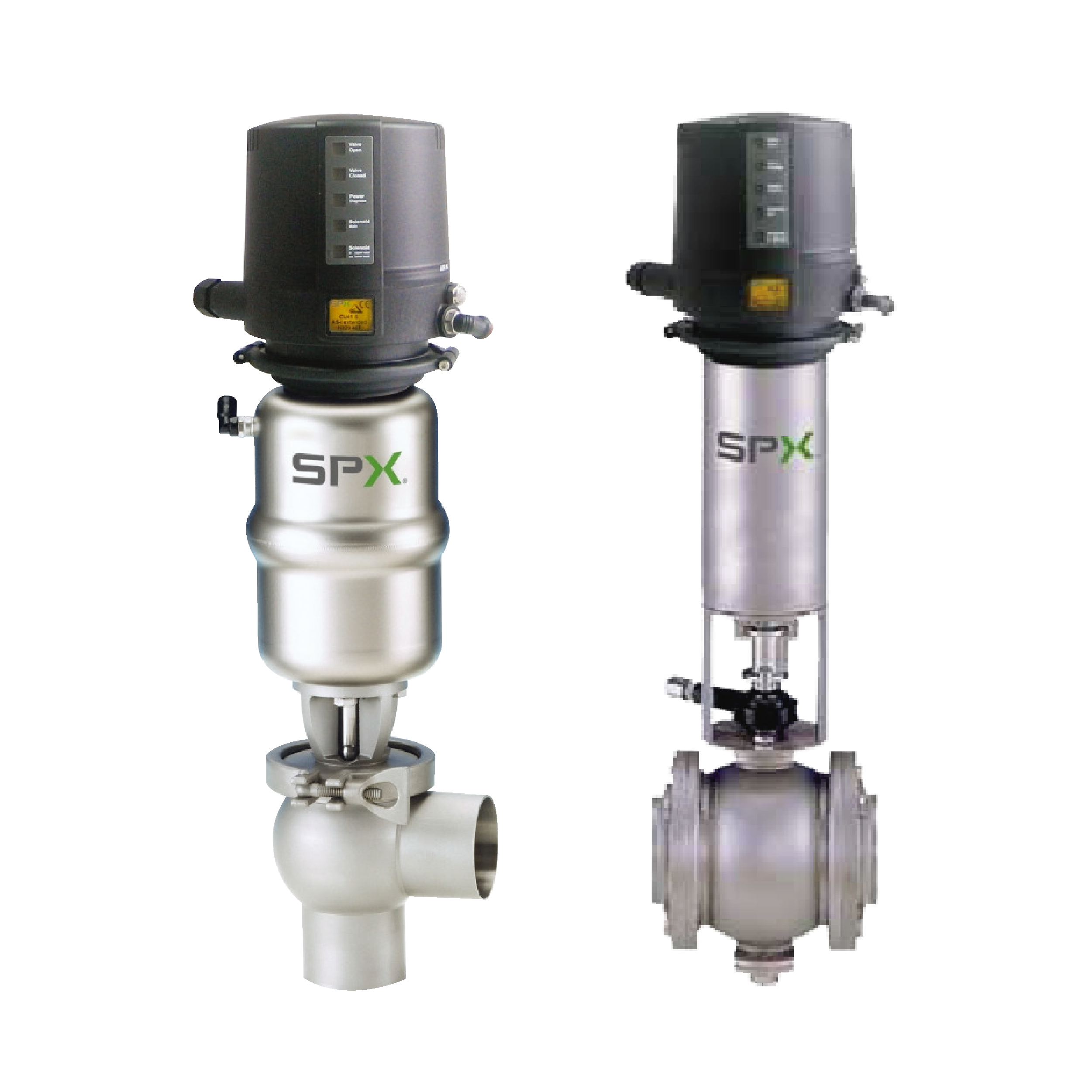

Sanitary process valves

| Technology | Single and double seated ball valves |

| Dimesions | 28 to 2,000,000 SSU / 1 to 440,000 cST |

| Pressure | 145 PSI (10 bar) |

| Temperature | 275°F/135°C |

| Control air pressure | From 87 PSI (6 bar) to 116 PSI (8 bar) |

Benefits:

APV double seated ball valves are proving their value day by day in the fields of brewing, beverage technology, dairy and food industries, as well as in chemistry. Double seat valve

The application field of the APV valve comprises the separation of two line sections with different fluids by two independent seals with an intermediate leak chamber and free drainage to the atmosphere.

They were specially developed for use in industries where protection against product mixing is given the highest priority.

Main characteristics and advantages:

Safe separation of incompatible fluids by two independent seat seals.

Suitable for pigging systems.

Timely detection of leaks in case of gasket wear.

Easy seal replacement

Safe design water hammer

Hygienic design ensures no product residue remains.

CIP cleaning connections to clean the leak chamber.

Compact construction that saves space.

The ball valve design provides full pipe diameter (full gauge), there is no deviation or narrowing of the product.

All contact parts of the product are made of AISI 316L / 1.4404 (DIN EN 100888) stainless steel. Available sealing materials are EPDM (standard), HNBR, FPM, VMQ (options). The ball seal is made of PTFE.