WHAT SOLUTIONS DOES IT PROVIDE?

As a general rule, medical vacuum systems are compact and easier to operate than industrial vacuum systems, but they are also reliable and durable when used properly. They can be made standard or have a more mobile view, with a handle to facilitate the movement of medical personnel and the wheels.

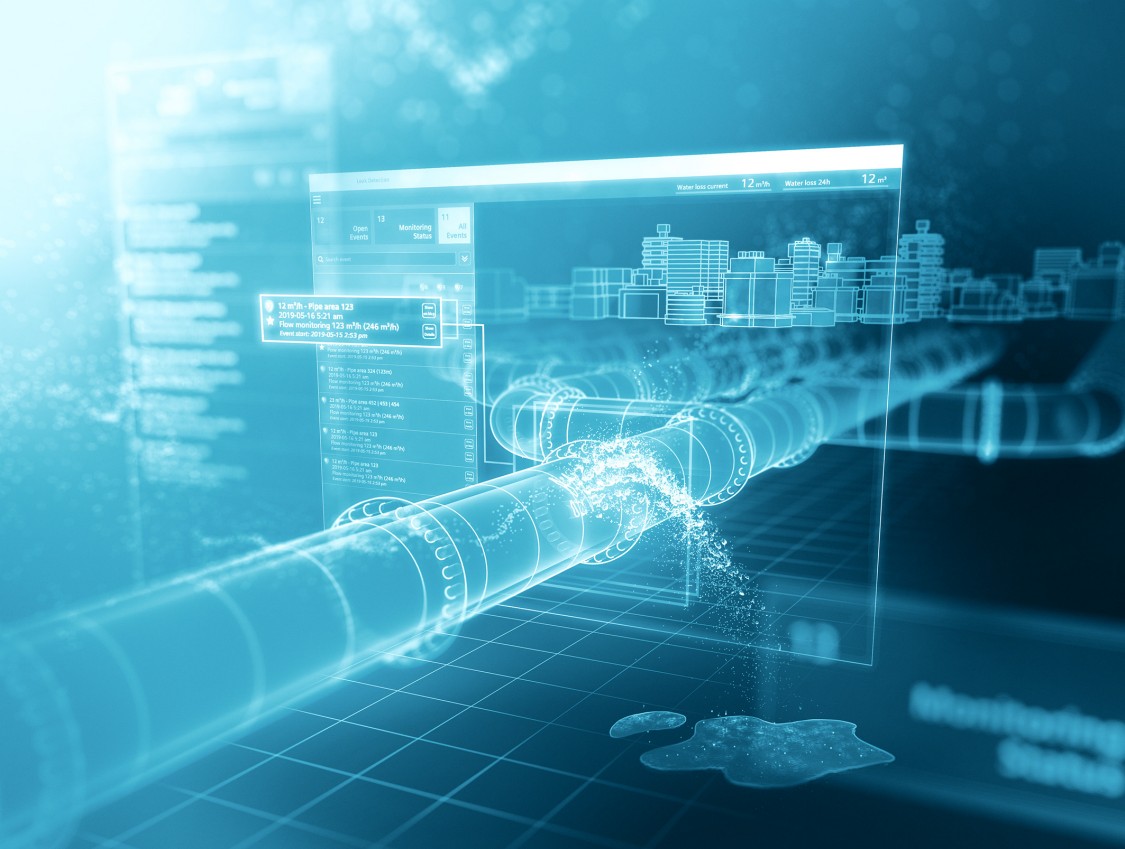

Vacuum systems can have one, two, or three pumps, depending on the usability in a particular area. The space at the base of a pump is applied where it is necessary to constantly maintain a space in the process. The installed vacuum pump provides 100% of the required capacity. In turn, the pump is activated automatically, depending on the level change in the vacuum.

Vacuum systems consisting of three rotary type vacuum pumps are used in test centers or provide a large plant with a central vacuum. The main objective of these devices is to provide consumers with the necessary level of vacuum, regardless of the circumstances. Without these pumps, hospitals would not be considered modern and the existence of companies and factories would be unthinkable since failure in production or infection is not desirable in any sphere and can adversely affect the operation.

In total, about 20 parameters are stored in the memory of the control unit, which is responsible for the operating algorithm of the system. Everything is loaded into the block by default and is ready to go. The operator can adjust many parameters using buttons on the front panel of the control unit, if desired or according to company rules. The packaging of medical vacuum systems includes antibacterial filters with a bypass line, which replaces the filters without separating from the process. Powerful suction systems: industrial vacuum cleaners to remove dirt and dust at the source of their formation.

To read more about this product, click here.

All devices in the system are equipped with individual frequency converters that operate on average with a capacity of about 65% and therefore save energy compared to individual units or installations without controlling the rotational speed.

How the medical vacuum system is applied:

• Gas supply systems for mechanical ventilation and anesthesia mechanisms.

• Drainage of wounds, cavities, including the thoracic cavity,

• Endotracheal tube cleaning.

• The collection of excess blood and fluids.

• The main parameters of the selection of the medical vacuum system:

• The gas flow must match the volume and efficiency of the receiver.

• Power and number of pumps are interconnected.

• Residual pressure and limitation: the minimum pressure created by running the pump without pumping.

• The lowest working pressure is the lowest pressure level at which the appliance normally operates, that is, the pressure in economy mode.

If you are interested in receiving a quote or consulting with our representatives, click HERE.