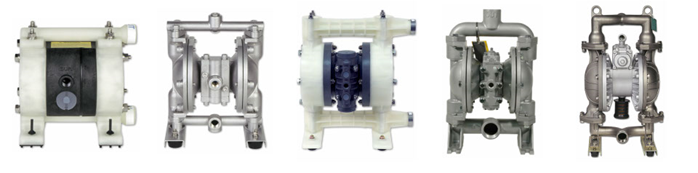

Pneumatic pumps, also called double diaphragm pumps, use compressed air to generate enough force to move fluids through piping systems.

Its application is very similar to that of hydraulic pumps, with the difference that the pneumatic pump uses air, and the hydraulic pump, fluids of any kind to move the internal parts.

These types of pumps are generally used in industrial sectors. Next, we will briefly tell you what a pneumatic pump is and what its applications are.

What is a pneumatic pump?

A pneumatic pump is a positive displacement pump that is driven by pressurized air to transport products and fluids.

Therefore, being pneumatic, it takes advantage of the energy of the air to transmit it to the fluid, increasing its pressure and generating a flow.

Operation of a double diaphragm pneumatic pump

Its working principle is based on a double diaphragm, which is connected by a shaft in the center, which allows the cameras to move at the same time. Therefore, it is also a separation between the product and the compressed air. Through the pressure regulating valve it is possible to adjust the air required to have a higher or lower fluid flow.

What is it for?

Its operation makes it a widely used element in different industries, since it allows pumping fluids and corrosive products avoiding drips and contamination.

Thanks to the qualities of pneumatic pumps, they allow pumping clean or sterile fluids, liquids that are toxic or aggressive; sludge, heavy metals or sulfuric acid, among many others.

In this way it is used in industries of a very different nature: from the pharmaceutical industry to the chemical or mining.

This is because it can be used in the following situations: solids, liquids, semi-liquids and gases that should not contaminate the pump; situations where it is used to recirculate, cool or lubricate certain fluids; and even when cleaning products, petroleum or oils are transferred.

Advantages of using pneumatic pumps

As we have indicated, pneumatic pumps are elements that are used in practically any industrial sector, since they carry out the work in a simple way and do not contaminate the product.

In addition to being optimal for chemicals and fluids with large amounts of suspended solids, they are also self-priming, self-priming pumps that can work dry for short periods and even long periods without suffering constant damage as occurs in motor pumps. Electric (Except for Teflon diaphragm pumps which do not allow any period of dry working time). It does not need a safety valve, as it stabilizes automatically; and it is possible to regulate the fluid flow by means of an air pressure regulator.

If you have any questions about the usage of pneumatic pumps and their adaptation to your sector, contact us for more information.