Among the two types of pumps that we have at Inducom USA, we have differences that characterize each pump and that show which one specifically serves in the best way to pump chocolate.

Gear pumps

Gear pumps are used for pumping thick and viscous liquids like oil and chocolate. Gear pumps have separation gears on the inlet side of the pump, creating a vacuum that moves the liquid to carry it through the gears to the outlet of the pump. At the end of the gear engagement, the liquid is expelled.

For their part, gear pumps are also applied in boiler water injection processes. Process in charge of starting the processes of the industrial plant, emitting the steam that will put the machines into operation.

Lobe pumps

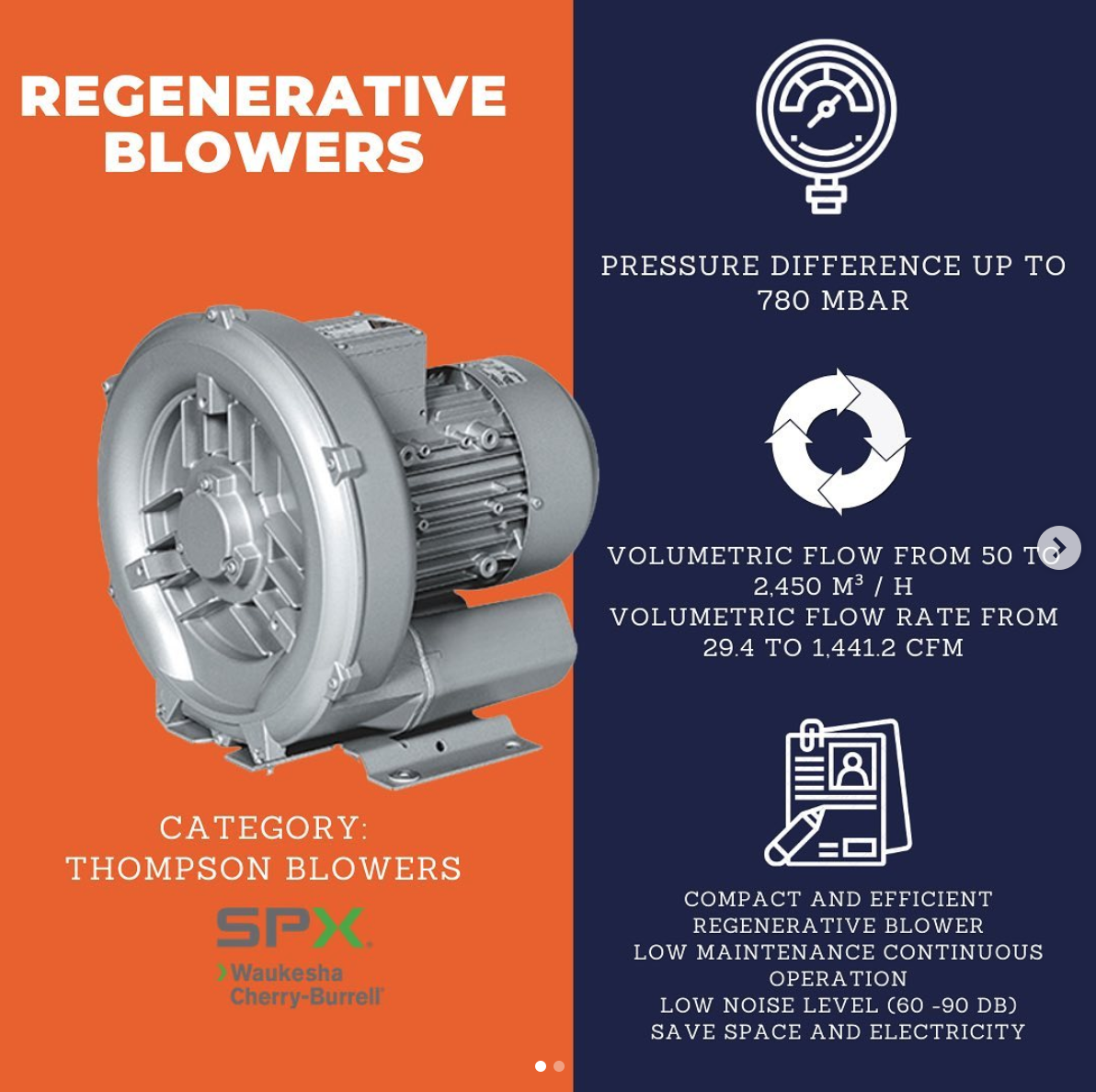

Waukesha high and low viscosity lobe pumps are presented as an entry solution for applications that demand a positive displacement pump with a sanitary design. They are designed for products that require temperature control such as sugars and chocolates. It also participates in hot water or steam to preserve heat without clotting.

These standard CPI capacity Waukesha lobe pumps handle both low viscosity and high viscosity products. Its operation emits a low sound level. These kits provide a double seal option.

For low shear flows they are ideal for transferring media such as starch paste, chocolate, sugar syrup, honey, jam, and slimy sauce products. These types of equipment must be selected according to their medium characteristics and technological requirements condition. At Inducom we have a permanent stock of spare parts for this equipment.

Click here for more information.