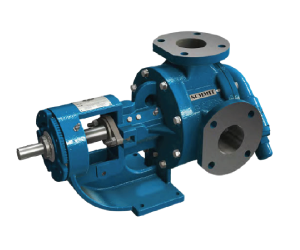

Gear pump are specifically used to pump thick liquids like oil and chocolate. The separating gears on the inlet side of the pump create a vacuum that moves the liquid to carry it through the gears to the outlet of the pump. At the end of the gear engagement, the liquid is expelled. We put at your disposal two types of external and internal gear pumps.

The SG, 432, and 32 Series of Universal Seal Gear Pumps maintain their anchorage in the process making it easy to change or replace the seal quickly and easily, with their innovative design. They have an oversized box where different types of seals are attached without modifying it. They also incorporate a large diameter bearing box that facilitates the assembly and disassembly of the seals.

One of its main advantages is that most seal maintenance operations can be done without removing the pump from the pipeline. Its applications stand out in the petrochemical industry, refineries, sugar, tire manufacturers, etc.

Roper Pumps

These are helical gear pumps intended for application in the industrial, transportation, and oil and gas markets. It has a wide variety of pumps for handling bulk liquids, high pressure. These worm gear pumps are self-priming, bi-directional cast iron with differential pressures at 125 PSI and up to 468 GPM.

More technical information about Gear Pump from Viking Pump

Benefits:

High efficiency over the full speed range, reliable and easy to maintain, shaft seal options Smooth flow without pulsing.

The Viking brand universal seal gear pumps maintain their anchorage in the process, facilitating the change or replacement of the seal quickly and easily, with their innovative design. They have an oversized box where different types of seals are attached without modifying it. They also incorporate a large diameter bearing box that facilitates the assembly and disassembly of the seals and the fast and precise positioning of the rotor shaft.

Most seal maintenance operations can be done without removing the pump from the pipeline, reducing downtime and maximizing equipment productivity.

Oils, Lubricants, Greases, Resins, Adhesives, Pulps, Rubber Solutions, Asphalt, Molasses, soap, Polyols, Isocyanates, Vinyl Chloride in continuous duty applications.