Maintenance and operation of pressure irrigation systems: Water is a component of our nature, it has been present on Earth for more than 3,000 million years, it occupies three-quarters of the planet’s surface. In our environment we find water: in liquid, solid and gaseous states in the atmosphere and clouds.

Drip irrigation

The Dropper

This is the most expensive part of irrigation. Based on this, all design calculations, filtering, maintenance, handling, pressure regulation, etc. are carried out.

All the management that is carried out in drip irrigation is to maintain the uniformity of the irrigation. Uniformity is the most valuable this irrigation and should be 95%.

What can we do to maintain that irrigation uniformity in pressure irrigation systems?

1.Know what are the specifications of the irrigation tape or hose.

2. Perform required maintenance.

What are the specs?

Work pressure

Filtration grade (microns 200, 150, etc.)

Dropper discharge

Distance between drippers

Product life or expected life of the hose or tape

Self compensated or not

Furrow length

Whether the dropper outlet is covered or not

FILTER AND FILTER SPECIFICATIONS

Most of the ring filters show the filter capacity in mesh (or microns) and sometimes like this example the volume of water.

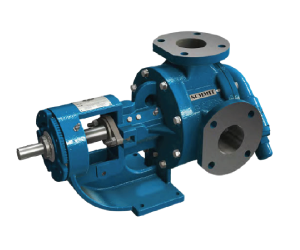

Centrifugal Pump Parts

1- Housing. Most of the housings are made of cast iron for drinking water, but have limitations with aggressive liquids (chemicals, wastewater, seawater). Another material used is bronze. Stainless steel is also used if the liquid is highly corrosive.

2- Impeller or Impeller. For pumping drinking water in small, medium and large flows, centrifugal impellers with radial and semi-axial blades are used. Made of iron, bronze, stainless steel, plastics.

3- Mechanical Seal. It is the most used mechanical seal, composed of carbon and ceramic. It is lubricated and cooled by the pumped water, so dry running should be avoided because it is irreparably damaged.

4- Drive shaft. In small monoblock pumps, the electric motor shaft extends to the pump, resting on the motor bearings. Made of stainless steel.

Get your Centrifugal Pump Right Here: https://inducom.us/product/centrifugal-pumps-2/

IRRIGATION CONCEPTS

Pressure irrigation systems

Flow

Volume divided into time, that is, it is the amount of water that a pump is capable of delivering in a given period of time. The flow rate is generally measured in: liters / minute l / m, cubic meters / hour m3 / h, liters / second l / s. Gallons per minute gpm etc.

Pressure

Force applied to a surface, example: a vertical column of water with an area of 1 cm2 by a height of 10 m, generates a pressure on its base of 1kg / cm2 due to the weight of the water contained, which in this case is 1 liter. From this test it is defined that 1kg / cm2 is equivalent to 10 mca (meters column of water) of pressure. In a pump, pressure is the force per unit area, which causes a lift. This elevation is commonly known as Hm (gauge head). Other pressure units are: psi, bar, atm.

Loss of Load

They represent pressure losses (mca), suffered in the conduction of a liquid. This means that the water as it passes through the pipe and accessories loses pressure, for this reason the pipe must be of the largest possible diameter, to reduce speed and friction.

Power

P. Absorbed; is the demand from the pump to the motor, commonly measured in hp, kw. This is the product of the flow rate times the head. If the efficiency of the pump is high, the lower the power demanded from the motor. The formula is: P.abs. = (Q x H) / (75 x%).

Nominal P. of a motor: it is indicated on its plate. It is expressed in Cv, Hp and kW (1 HP = 0.745 kW).

Priming

It is understood by priming a pump when the suction pipe is hermetic and is filled with water free of air. If the level of water to be pumped is lower than the pump, a foot valve must be installed to contain the water column when the pump stops.

Suction and discharge pipes

These must be dimensioned according to the flow rate and length, for max. 1.5 m / sec. and minimum pressure drops. The pipes must not be supported by the pump. The diameters of the pumps do not indicate the diameter of the pipes, these must always be calculated. It is advisable to use pipes with a diameter greater than those of the pump.

REQUIRED MAINTENANCE OF THE DRIP IRRIGATION SYSTEM

Inspection and maintenance of all system components.

That they work well and do not leak.

The handheld pressure gauge becomes the most valuable tool to maintain uniformity in the pressure of the irrigation system.

Important in the irrigation line is, if they are turbulent or laminar flow drippers and if they are self-compensating or not.

In general, all irrigation lines on the market are turbulent flow.

But only some have self-compensating drippers

Since most of you use irrigation lines, we will focus mostly on this topic.

Irrigation lines

The irrigation lines, as they are not self-compensated, we have to always place them level.

In general, what are the basic problems of a drip irrigation line ?: – Dripper obstructions • Silt, clays, etc.

Precipitates of Calcium Magnesium, Iron, etc.

Algae and Bacteria Growth – Leaks caused by:

Mouse, crickets, rabbits, etc.

Mechanical equipment

Staff

OBSTRUCTION OF DRIPPERS

Pressure irrigation systems

We have to remember that, once the dripper is clogged, it is extremely difficult and expensive to solve this problem, so all the management of the irrigation line must be preventive maintenance to avoid clogging.

The drippers can be partially clogged, causing a change in the flow of water, which is just as dangerous since it gives us unevenness of irrigation, causing us a decrease in the yield of the crop in the areas of that dripper.

Causes Loss of Uniformity in Pressure Irrigation Systems

Hydraulic Design

Quality of materials

System aging

System modifications

Deficiencies in the operation and maintenance of the system

Get your Centrifugal Pump Right Here: https://inducom.us/product/centrifugal-pumps-2/