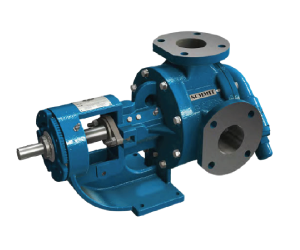

Pneumatic double diaphragm pump Yamada, also known as double diaphragm pumps are widely known to industry and engineering. These pneumatic diaphragm pumps are high performance for water treatment, mining, sludge handling in sewage and ink handling in print shops. In mining they are used for dewatering, loaded solids, sludge, water evacuation, utility, injection, filter press, transfer of oil and fuel.

When it comes to extracting minerals and metals from the ground, Yamada has the pumping technology to meet your dewatering and transfer needs. In the harshest conditions, Yamada diaphragm pumps have earned a reputation as the most reliable and durable pump on the market. All Yamada diaphragm pumps feature a completely non-lubricated air valve, bolt-on construction and maintenance-friendly design.

Pneumatic double diaphragm pump Yamada, work primarily for transferring corrosive and abrasive chemicals. As well as sludge and fluids with high concentrations of suspended solids, movement of Viscous fluids (up to 50,000 cps). They have capacities up to 950 liters / minute.

Among the main advantages that Pneumatic double diaphragm pump Yamada provide are the intrinsic safety they provide. They do not use an electric motor, which is often expensive. They handle high viscosity liquids, solids and loaded sludge. They are portable and submersible with flow rates from 1 to 215 gpm. They have the ability to run dry without damaging the pump. Allow the use of optional abrasion pads and shock absorbers.