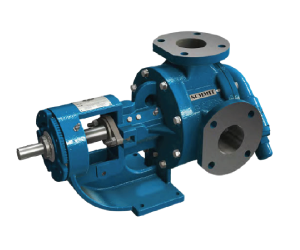

Viking Pump has been a trusted partner in the reliability of sugar cane and beet plants around the world, as well as terminals, food factories and food processors, for more than a century. They fabricate de positive displacement pumps Viking.

Viking invented the internal gear pump, and has developed unique models for the sugar industry that handle everything from thick juices to massecuite, magma and molasses, to syrups, betaine, and raffinate, with the same pump!

By changing the speeds, internal clearances and the idle gear (magma and massecuite only), most processes can be covered with one or two sizes of the same pump model. This standardization simplifies plant operation and maintenance, while increasing reliability and uptime.

Advantages of using positive displacement pumps Viking:

Low speed operation to minimize shear

An optional splined idle gear to prevent damage to glass …

A shaft seal, or gasket, or hard face mechanical seal

The sealing between the bearings limits radial and axial movement for longer seal life.

End gap is adjustable for viscosity or to compensate for wear

Hard parts for longer life with abrasive glass

Thrust bearing positively maintains rotor position

Constant flow without pulsation which can cause liquid / solid separation

Reversible direction of flow to the belt line after pumping to prevent solidification

A robust design that forgives operator error

Inducom has stock and import equipment, depending on the requirement.

Here are some pump models used in the sugar industry: