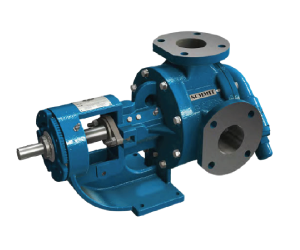

Even before the fire station has been informed and fire brigade personnel are in action, fire pumps are ready to rescue us from a catastrophic disaster. A Ruhrpumpen fire pump is a component responsible for supplying adequate water pressure to sprinklers and hose risers to control or contain a fire.

What types of fire pumps are there?

The centrifugal pumps are the most used in fire protection systems, including horizontal split case, end suction horizontal, turbine vertical line. These pumps are commonly driven by an electric motor or a diesel engine.

Furthermore, a pump is provided maintenance of pressure for flow small and pressure relatively high, commonly known as Jockey pumps in a system fire water to keep the fire system pressurized under nonfire and prevent cycles unnecessary of the main fire pump.

How does a fire pump work?

Fire pumps are designed to start automatically when the water pressure drops below a threshold in a fire system. Pressure drops occur when one or more sprinkler heads or a hose riser opens and discharges water.

It is important to note that, contrary to popular belief, the sprinklers are not activated by smoke and not all of them are activated at the same time. If that were the case, sprinkler systems would do more harm than good, drenching all of your assets. The only sprinklers that activate are those that are directly subject to the heat caused by a fire.

Each sprinkler has a small glass bulb that contains a heat-sensitive liquid inside. When the ambient temperature of the liquid reaches a certain level, usually between 57 and 77 degrees Celsius, it will expand the liquid and break the bulb, which in turn releases water from the sprinkler head. It is important to mention that most fires generally require one or two sprinkler heads to be contained or extinguished.

Ensuring that your fire fighting pump system meets safety regulations and standards is essential for safety. All fire pump installations must meet the requirements of local regulations and applicable fire codes.

Fire pumps must be tested and listed by authorized and recognized laboratories such as Underwriter’s Laboratory (UL) and listed by accredited agencies such as Factory Mutual (FM).

In addition, the installation of your fire suppression system must comply with the latest edition of the NFPA 20 standard. The National Fire Protection Association ( NFPA ) is a global non-profit organization, established in 1896, dedicated to eliminating deaths, injuries, property, and economic damage due to fire, electricity, and related hazards.

Inspection, testing, and maintenance of a fire pumping system

Fire pumps and their associated components require periodic testing, inspection, service, and maintenance to ensure proper operation. To help ensure reliable pump operation in the critical stage of an incident, qualified personnel should conduct periodic visual inspections and function tests. This includes, but is not limited to, checking the water supply and pump suction conditions, discharge piping, and valves, electrical system conditions, motor consumable levels, etc. It is important to ensure that inspections are carried out at the correct intervals and that they are carried out. properly documented.

To meet federal certification requirements and state licensing requirements, automatic fire pump systems must be inspected, tested, and maintained following NFPA 25, Standard for Inspection, Testing, and Maintenance of Systems. Water-Based Fire Protection.